We provide the following services:

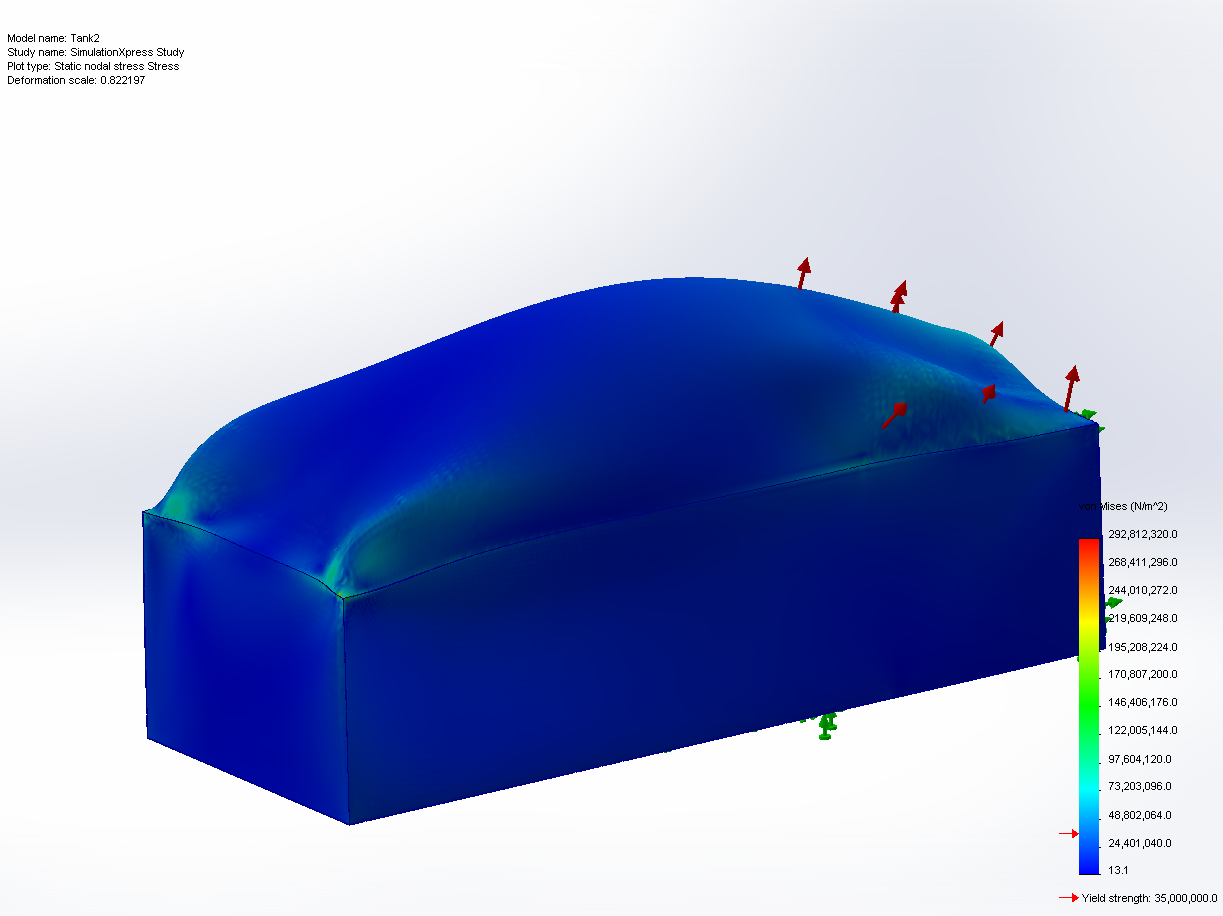

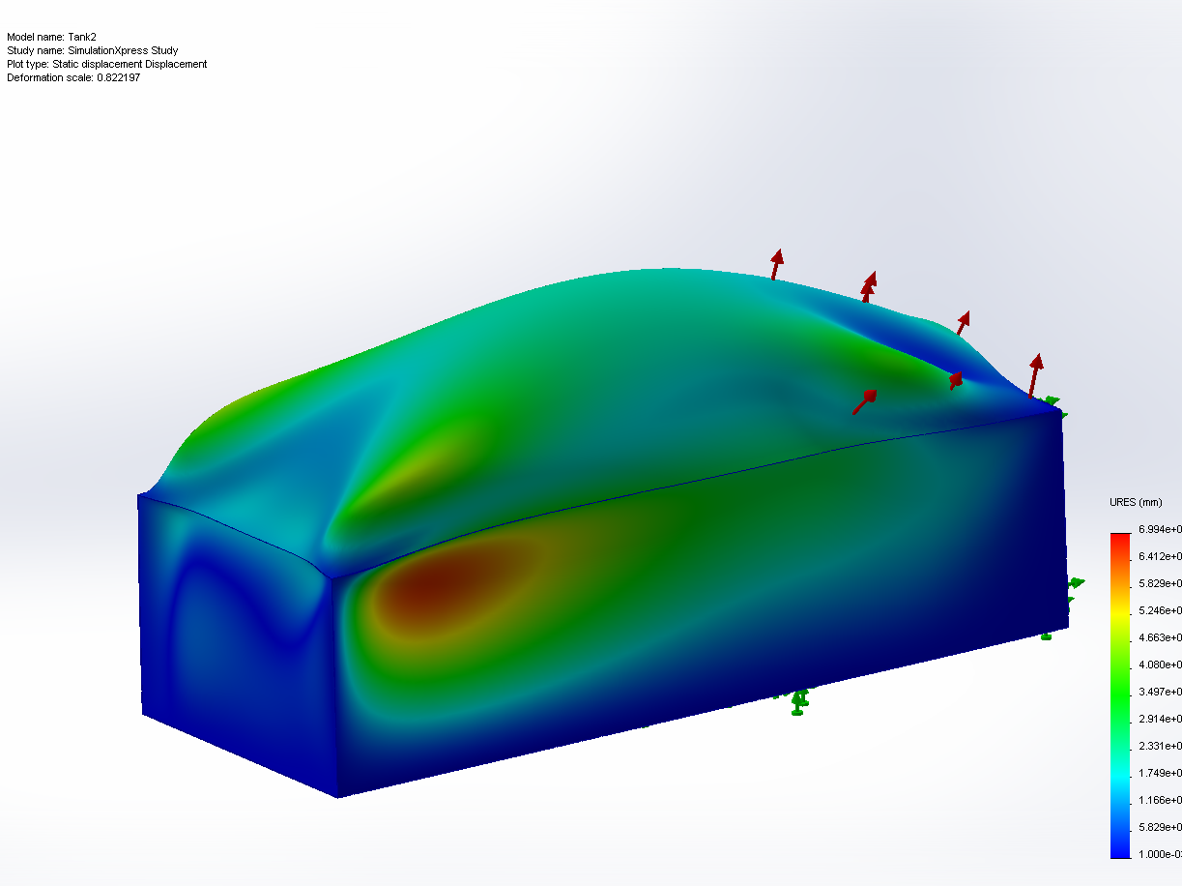

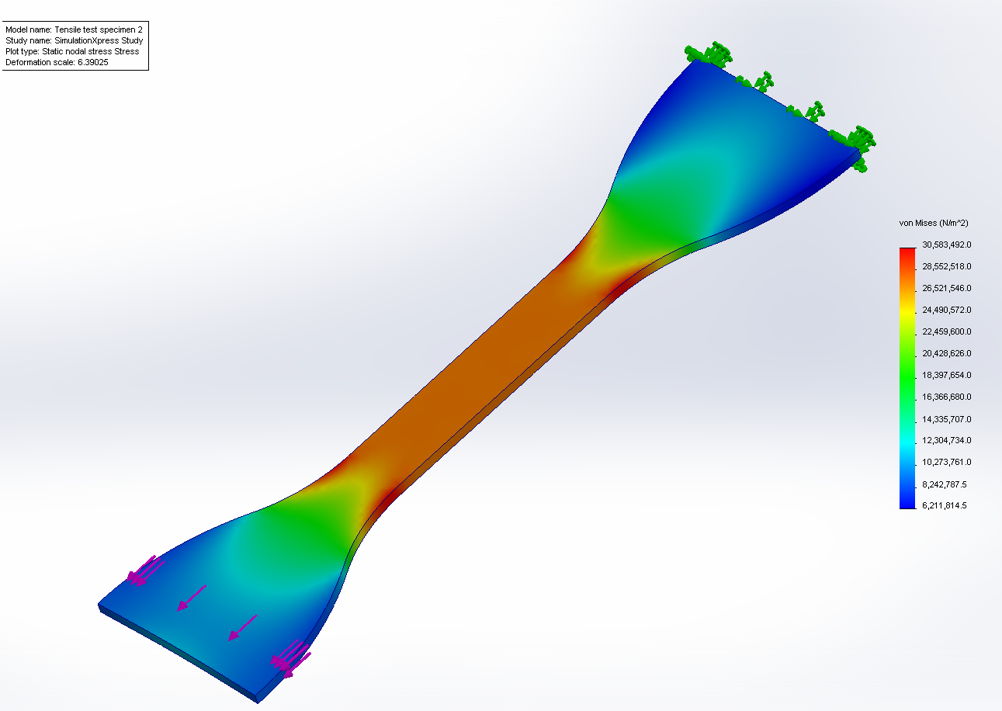

We specialize in the design of flexitank and associated systems to ensure you enjoy the best possible tank and structure there is. An early focus on tank design and structure translates into tangible benefits in manufacturing and operation of the tank later on. A poorly designed tank is guaranteed to lead to manufacturing defects as well as a whole host of operating problems. We make sure each design is tailored to your specific application and needs. We also guarantee the tank will be designed to achieve the lowest possible surface area for the volume under consideration. This is extremely important in markets such as wine and pharma where through-wall contamination can be a concern. Every design will be built and analyzed using 3D CAD modeling and analyzed for stress accordingly under a number of dynamic force scenarios to ensure the tank performs as required. We do not believe there are any other organizations offering this level of design and technical service. We believe it is far cheaper to prevent leaks than repairing or cleaning them up once they happen.

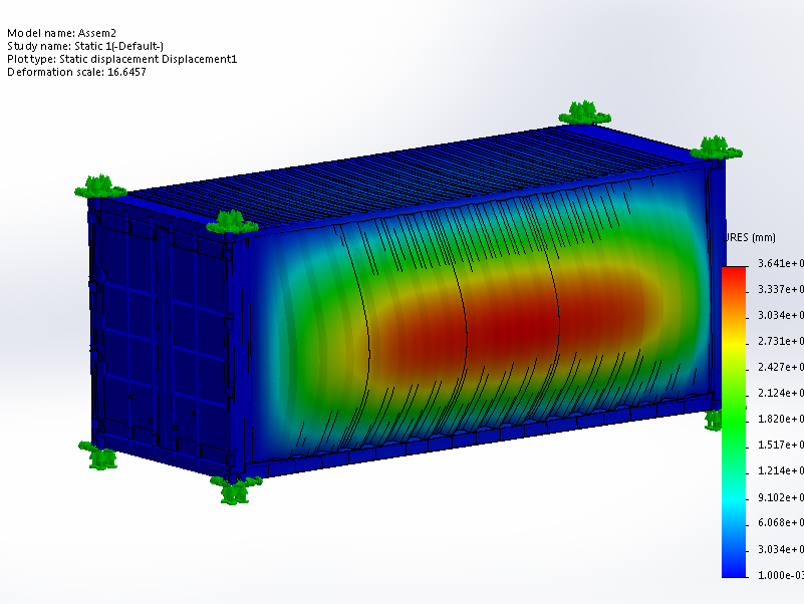

Below are a set of images depicting typical analyses we carry out from tank sizing and modeling for stress and movement under load, to material testing and final interface with the shipping container.

"

" "

" "

" "

"

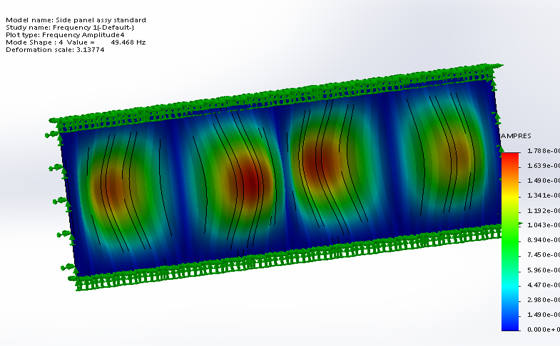

Below is an image from a frequency analysis we carried out on the side wall of a shipping container to determine modal frequencies. This is an important consideration when dealing with dynamic loads and their effect on the container side walls and surrounding structures.

Below is an animation of a flexitank under longitudinal surge. Notice the areas of imposed stress.

Below is an animation of a corner lock (container bridge clamp) assembly.

Below is an example of a packaging design project optimizing volume and mass properties as well as cost and quality concerns.